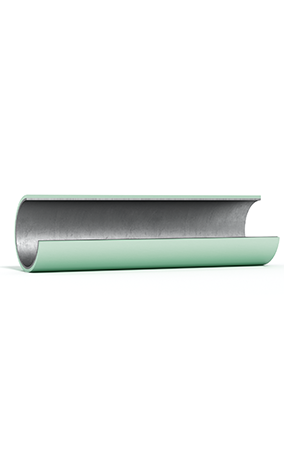

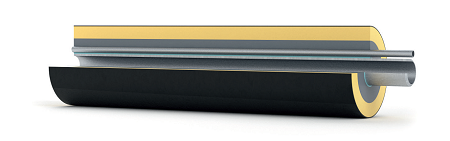

Steel pipes Ø 2.24-32.28 in. with outer two-and three-layer polyethylene coating

Hit

TMC Group Managing Company LLC provides steel pipes Ø 2.24-32.28 in. with outer two-and three-layer polyethylene coating (TU 1390-001-67740692-2010, TU 24.20.13-117-78682242-2022).

Details

Steel pipes Ø 2.24-32.28 in. with outer two-and three-layer polyethylene coating

Purpose

For reliable and durable corrosion protection of the outer surface of steel pipes, pipe sections, insulated in the factory:

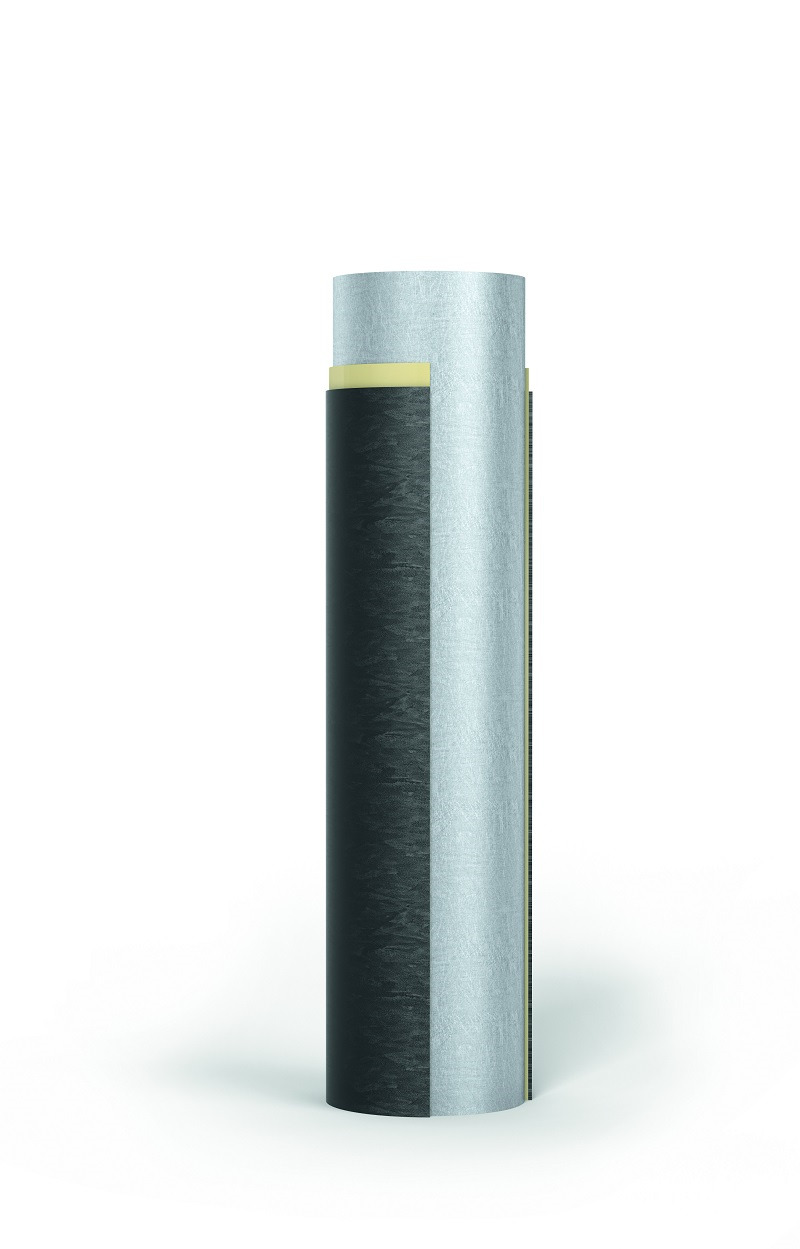

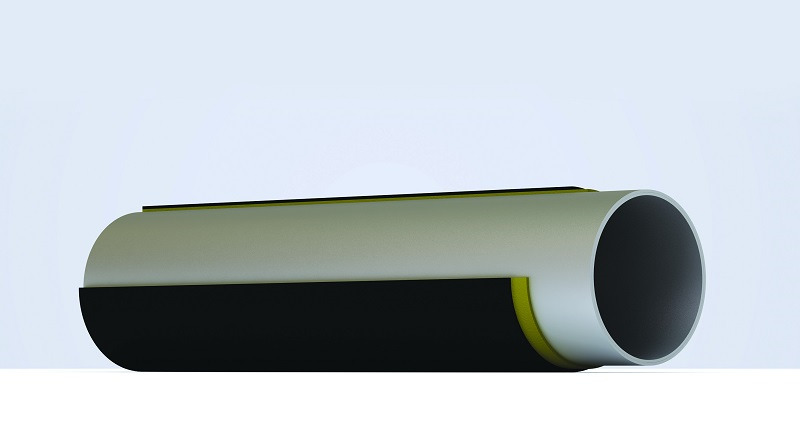

- two-layer outer protective coating based on extruded normal and reinforced polyethylene of ø 2.24-32.28 in.;

- three-layer outer protective coating based on extruded normal, reinforced, heat-resistant, and special-purpose polyethylene of ø 3.50-32.28 in.

Field of application

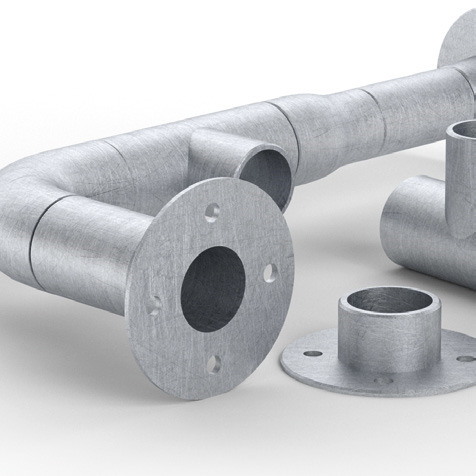

It is used in construction of main and field gas pipelines, oil and water pipelines, as well as in the construction of engineering networks (water conducts, sewage).Advantages

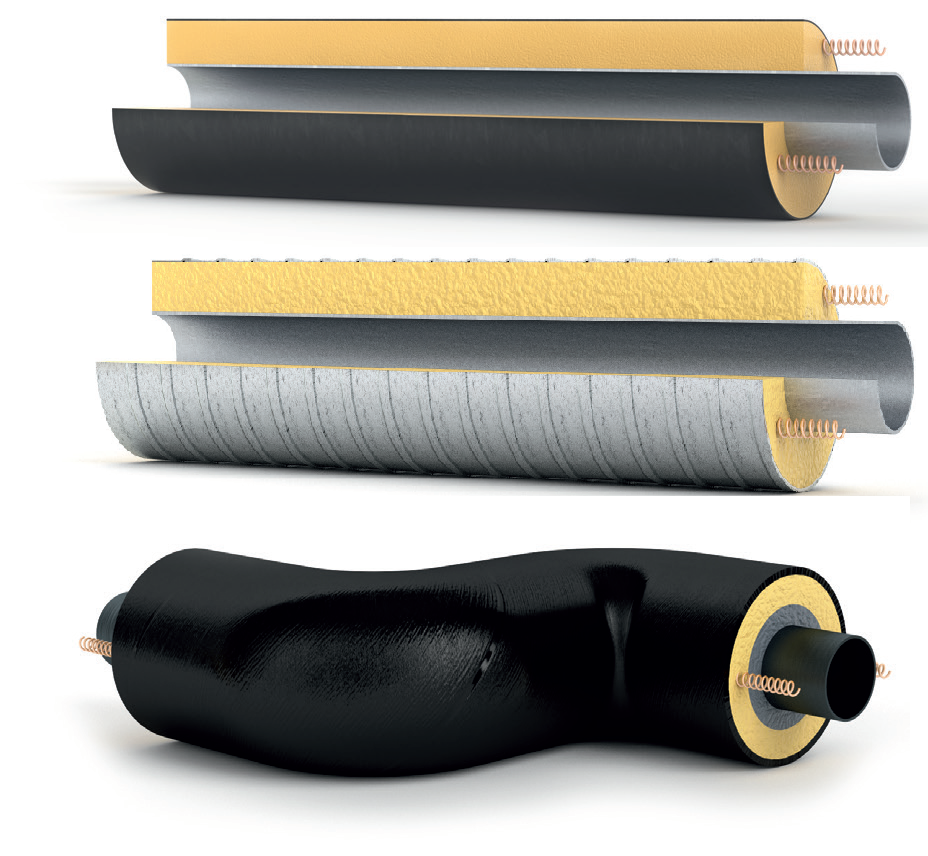

- Compared to traditional bitumen-mastic and polymer tape coatings, the factory polyethylene pipe coating has a high impact strength, enhanced adhesion to steel, resistance to forcing through, puncture, abrasion, and abrasive wear. Due to high adhesion, it is resistant to shear loads arising from setting of ground and in the course of shifting of pipeline sections during operation.

- The quality of the external polyethylene coating of pipes and pipeline parts, as applied in our conditions, meets the requirements of GOST R 51164-98, GOST 9.602-2005, GOST 31448-2012. Products are certified.

- Three-layer polyethylene pipe coating structurally differs from the two-layer one by the presence of another layer, an epoxy primer. The epoxy layer provides an enhanced coating’s adhesion to steel, water-resisting adhesion and resistance to cathodic disbonding. The polymer adhesion sublayer is the second, intermediate layer in the structure of the three-layer coating.

- Maximum operating temperature up to +176 °F.

Characteristics

Chief specialist

Phone number

E-mail

See more