Pipes, heat-insulated with polyurethane foam for underground and above-ground routing

Recommended

TMC Group Managing Company LLC provides pipes, heat-insulated with polyurethane foam for underground and above-ground routing.

Details

Pipes, heat-insulated with polyurethane foam for underground and above-ground routing

Purpose

Foam polyurethane (hereinafter referred to as FPU) thermal insulation is designed to maintain the temperature of the pumped medium and protect the outer surface of steel pipes and shaped parts of pipelines against corrosion in combination with corrosionresistant coatings.Field of application

- Heat supply systems.

- Hot-water supply systems.

- Transportation of highly viscous petroleum products.

Schedule of diameters

From 1.26 to 20.87 in.—for pipes thermally insulated with FPU; 6.26 to 20.87 in.—for pipes with combined insulation.Operating temperature

- 284 °F—operating temperature (for pipes thermally insulated with FPU).

- 302 °F—peak temperature (for pipes thermally insulated with FPU).

- 464 °F (for pipes with combined thermal insulation).

- 680 °F (for pipes with combined thermal insulation).

Advantages

Pipelines in foam polyurethane thermal insulation allows to:- reduce the heat loss 2-2.5 times compared to conventional materials;

- when using the Operational Remote Control System (ORCS), monitor damage to the pipeline thermal insulation;

- reduce the cost of capital construction 1.5 times as compared to trenched pipelines in conventional types of insulation;

- reduce the annual cost of heating network operation 9-10 times;

- operate the pipeline over the long term without repair.

Reliability

- Ensured by the factory assembly, made in the shop environment.

- High-quality waterproofing, which is ensured by a protective shell and monitored over the entire service life of the ORCS.

- Ensured by the strength of the FPU in compression and bending in the limits of the standard value of GOST 30732-2006.

Product Advantages

- Minimal thermal conductivity.

- Resistance to mechanical stress.

- No reaction with chemically active medium.

- High heat and energy saving performance.

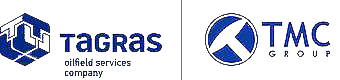

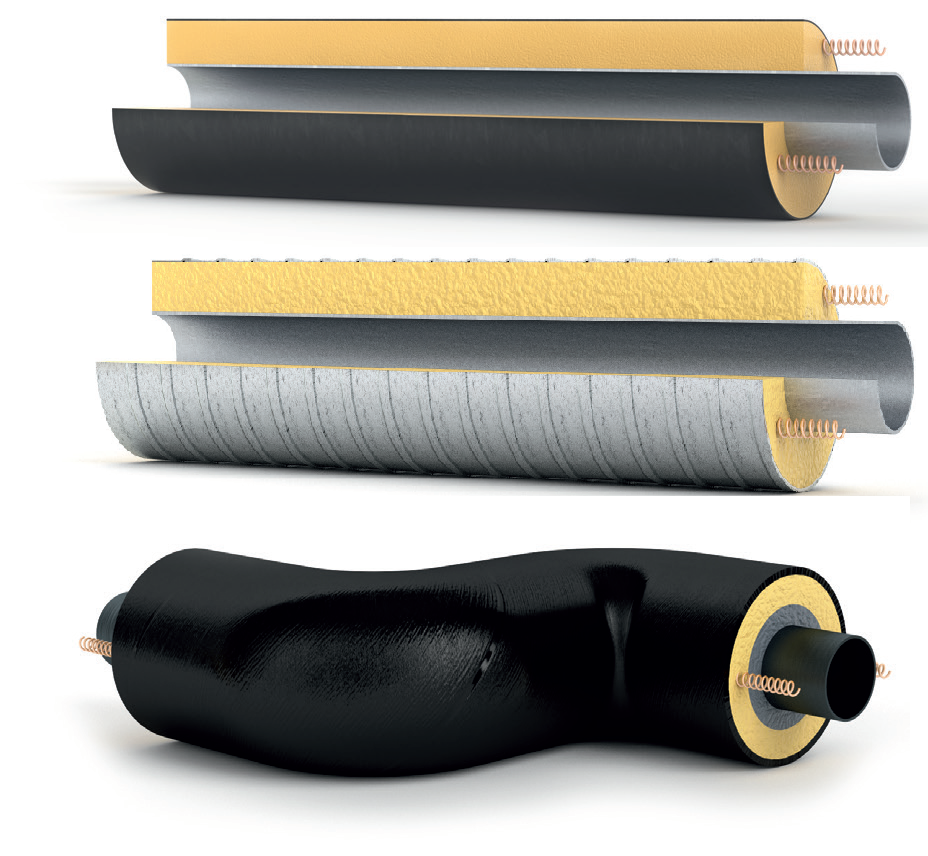

TYPES OF HEAT-INSULATED PIPES

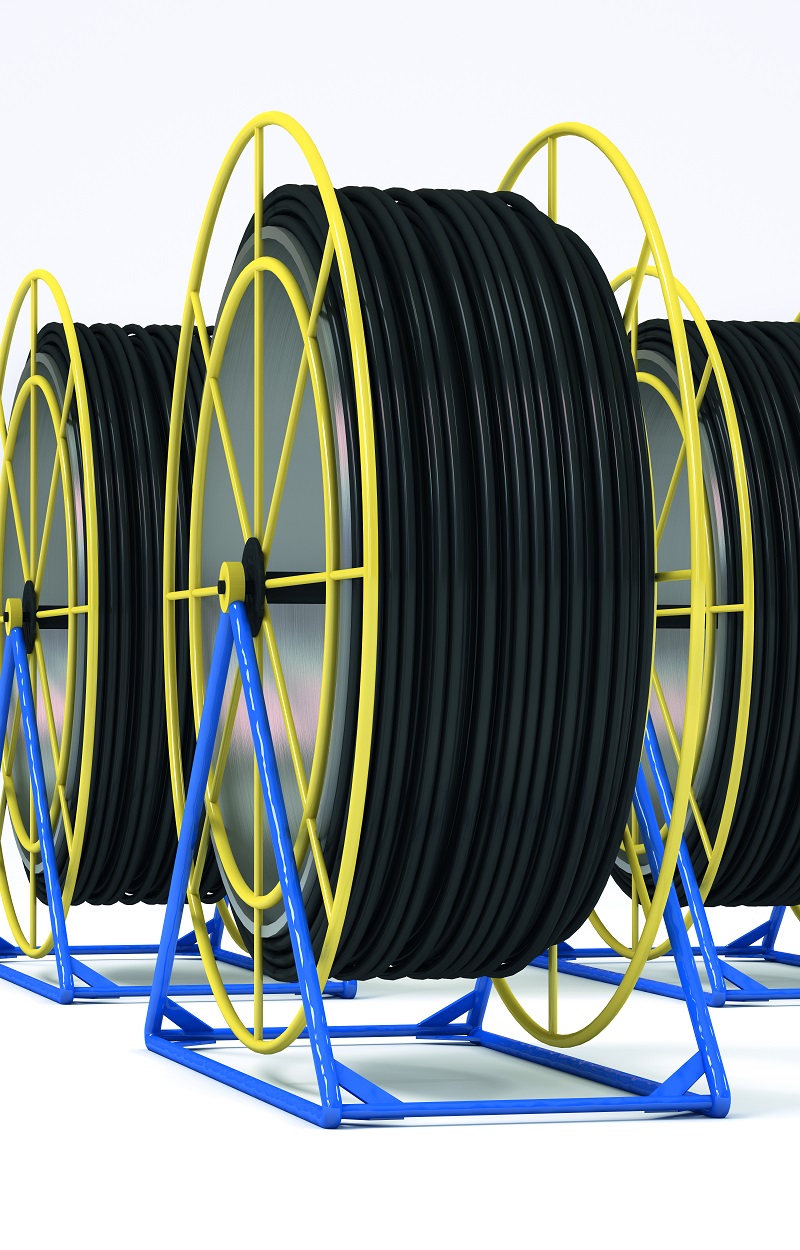

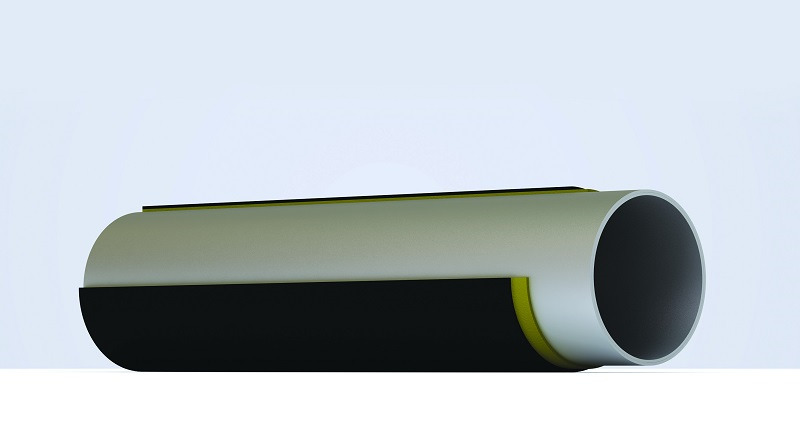

Steel pipes heat-insulated with polyurethane foam, equipped with ORCS (TU 24.20.13-118-78682242-2022)

- p/e sheathing;

- FPU;

- signal wire for ORCS;

- steel pipe.

- galvanized or metal-polymer sheathing;

- FPU;

- signal wire for ORCS;

- steel pipe.

Steel pipes with combined sheathing, equipped with the system ‘‘skin effect’’

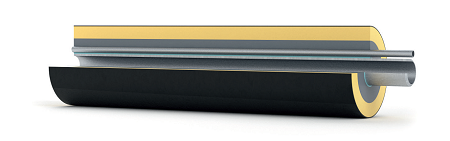

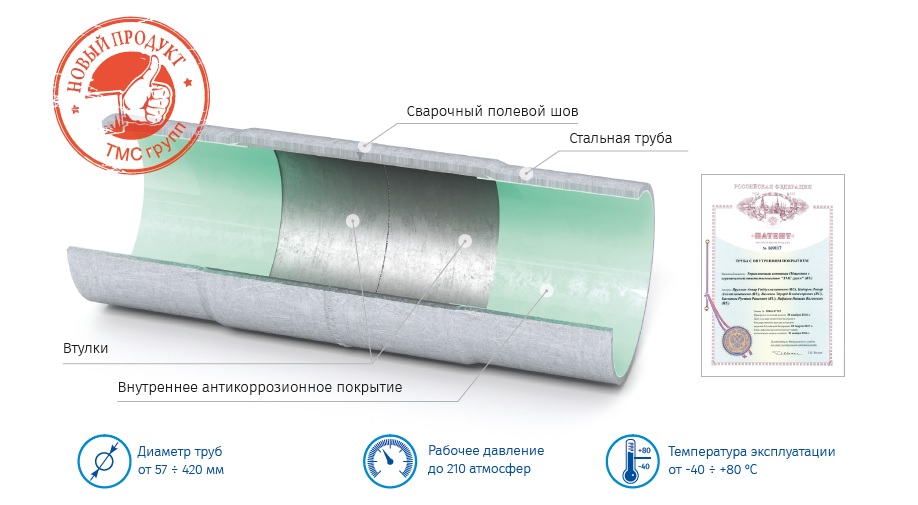

Pipes and pup-joints of steel, insulated with polyurethane foam, equipped with fire-prevention inserts

Purpose

To ensure reliable fire safety of a heat-insulated pipe by eliminating the possibility of spreading fire over the entire length if ignition of its combustible heat-insulation occurs.- At the request of the customer, it is combined with an internal corrosion-resistant coating and a sleeve to protect the heat-affected zone.

- At the request of the customer, all products can be equipped with linear indicators - the system of Operational Remote Control System (ORCS) or the ‘‘skin effect’’ system.

Characteristics

Documents

Chief specialist

Phone number

E-mail

See more