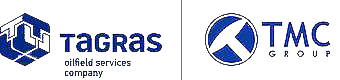

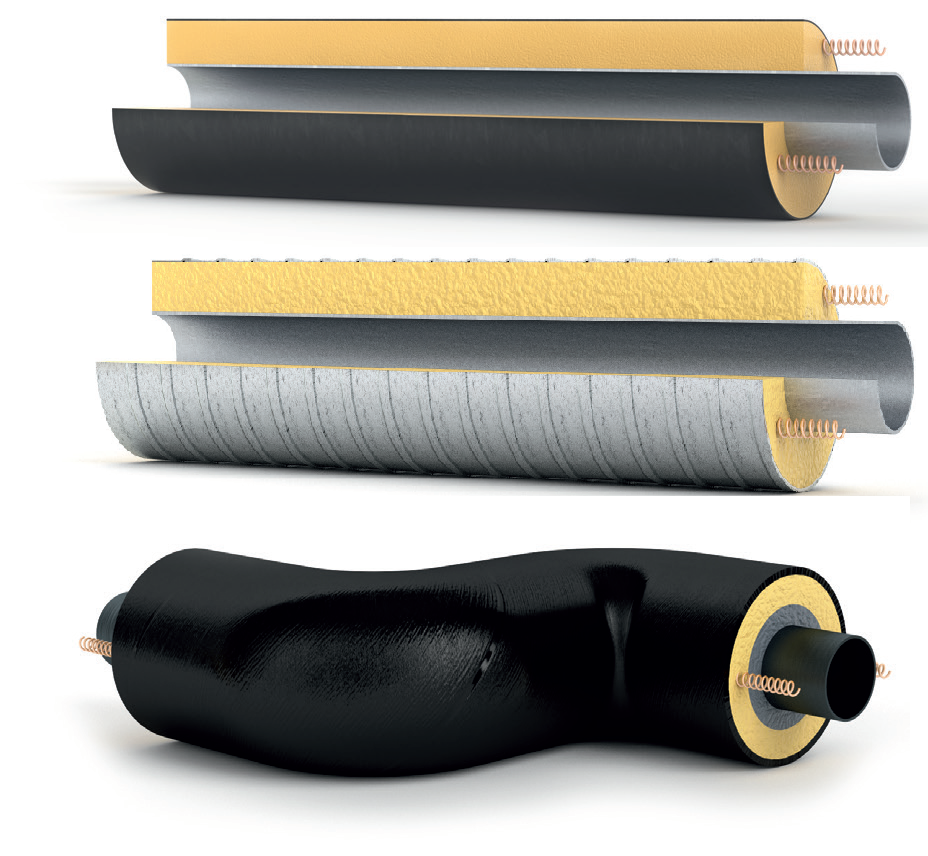

Metal-sprayed coating of end sections of pipes and pipeline parts with an internal corrosion-resistant coating (MPK)

Recommended

TMC Group Managing Company LLC provides metal-sprayed coating of end sections of pipes and pipeline parts with an internal corrosion-resistant coating (MPK).

Details

Metal-sprayed coating of end sections of pipes and pipeline parts with an internal corrosion-resistant coating (MPK)

Purpose

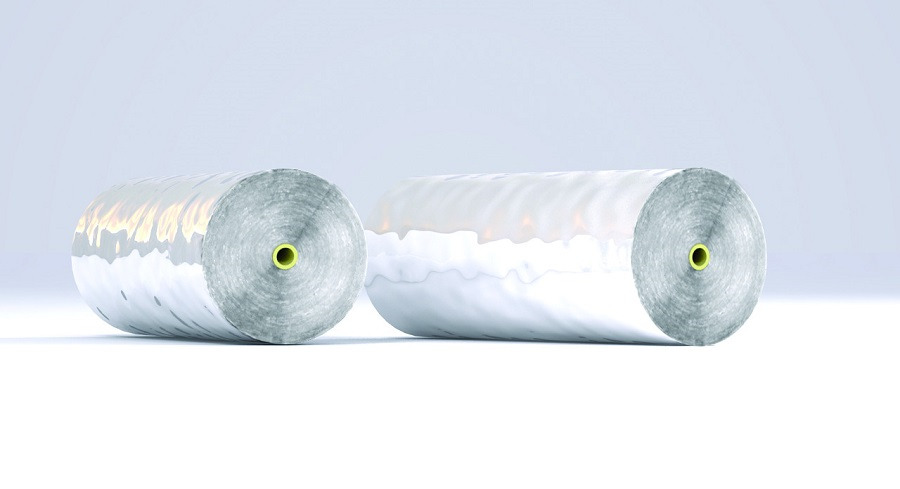

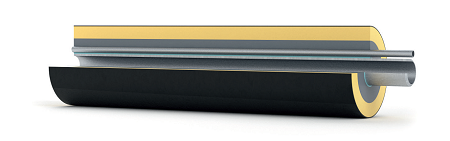

Metal-sprayed coating (MPK), used to protect the end sections of pipes/parts with a press-fitted sleeve, is designed for corrosion rotection of the inner surface of the welded seam and the heataffected zone.Advantages

Technological effectivenessThe inner pipe diameter is unchanged, which allows to:

- use mechanical aids for pipeline cleaning (scrapers);

- avoid creation of additional local resistance to fluid flow in the place where the sleeves are installed.

Minimizing labor costs

- Up to 46% cheaper than installing conventional sleeves in the field.

- Prevents the ingress of highly corrosive components of the environment to the metal of the welded joint.

Reliability

- The fixed sleeve mounting force and the sealant used ensure high insulation reliability in the heat-affected zone.

- High barrier properties of the weld protection system.

Field of application

In industrial pipelines transporting aggressive corrosive fluids:- Pipes;

- Pipeline parts;

- Pipe sections.

Reasons to choose our products

- We will choose the type of external anticorrosive protection of the pipelines depending on the operating conditions.

- Investigation of the welding joint microstructure of the pipe and bushing ends showed no corrosion damage during field trials.

Manufacturer warranty

Service life of pipes with external paint-and-lacquer coating and metalized pipe ends is at least 15 years.Characteristics

Chief specialist

Phone number

E-mail

See more