Purpose

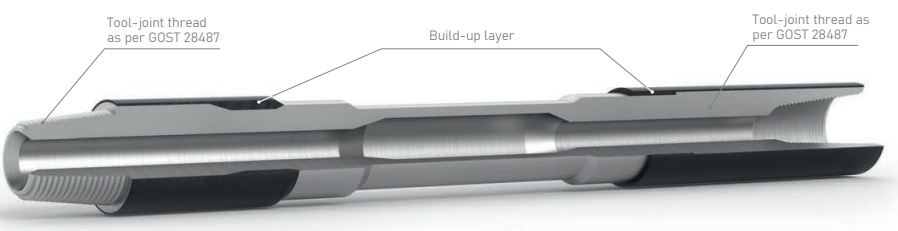

The company performs diagnosis and overhaul of drill pipes using a unique technology of metal build-up on the surface of interlocking parts.In the process of overhauling of the drill pipes the following operations are carried out:

- mechanical cleaning of the outer and inner surfaces of the pipe;

- diagnostics of smooth pipe wall thickness by ultrasonic flaw detection;

- determination of the geometric parameters of the surfaces of the interlocking and threaded parts;

- straightening of pipes in order to restore straightness;

- metal build-up welding on the surface of the locks with their extension along the pipe body using a unique patented technology;

- machining of the build-up surfaces of locks until their dimensions are fully restored;

- re-cutting of threaded parts on state-of-the-art CNC machines.

Advantages

- The main advantage of the proposed technology is the restoration of the interlocking part of the onworn pipe to the condition of a new pipe. The built-up metal is precisely matched in its properties to the quality of the pipe interlock metal, as a result of which the wear resistance of the restored surfaces is not inferior to the new pipes, and machining of the built-up surfaces is carried out until a full recovery of the geometric dimensions as per GOST 28487.

- The entire technology for building-up the interlock parts is realized on specially designed equipment installed in the process train has the appropriate certificates and permissions for application.