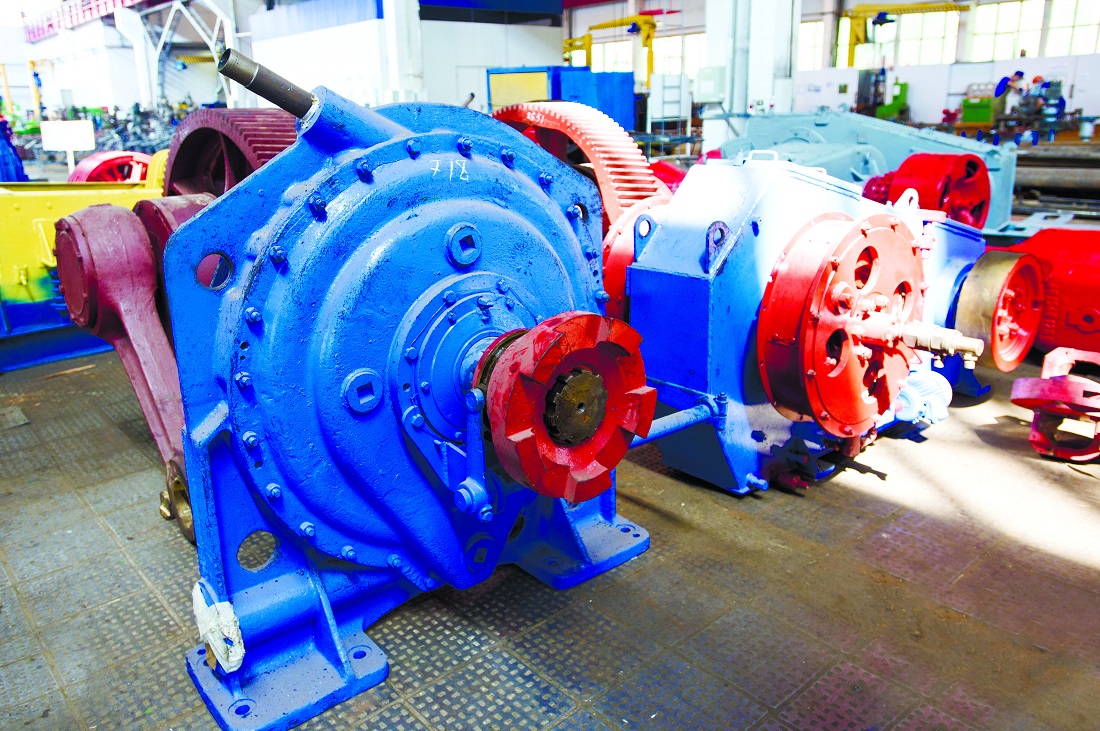

The repair of drilling equipment involves the following repair and recovery techniques:

- reconditioning of body parts, shafts by build-up welding;

- manufacture of new parts, including repair dimensions;

- heat treatment and surface hardening;

- restoration by polymeric coating of working surfaces;

- manufacture of fabricated rubber products;

- manufacture of metalware;

- trial run and hydraulic tests on special-purpose test benches.

We perform the overhaul the following types of drilling equipment and drilling pumps:

- Russia (Volgograd plant of drilling equipment: BU-75, BU-1600/100, BU-2000/125E, BU-2000/125EBM, BU-2500, BU-2900, BRN-1, NBT-600; Uralmash: UNB-600, NBT-950; Izhdril: 8T-650; KMZ: A60/80);

- USA, Canada (Dreco, Kremco, Ideco, Cardwell, IRI, Cabot, Gardner Denver, Brandt);

- China (Honghua, SLS).

Repairable equipment

- swivels;

- lifting and transmission shafts of drilling rigs;

- chain reducing gear, bevel gear speed reducers, gearboxes;

- rocker-machine gearboxes;

- crown blocks, traveling blocks;

- hooks, hook-blocks;

- vibrating screens;

- rotors R-560, R-700, R-410;

- hydraulic brakes;

- crankshafts and transmission shafts of drilling pumps;

- hydraulic boxes of drilling pumps BRN-1, UNB-600, 8T-650 etc.;

- top drive systems.