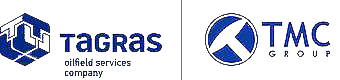

Polyethylene pipes

TMC Group Managing Company LLC provides polyethylene pipes.

Details

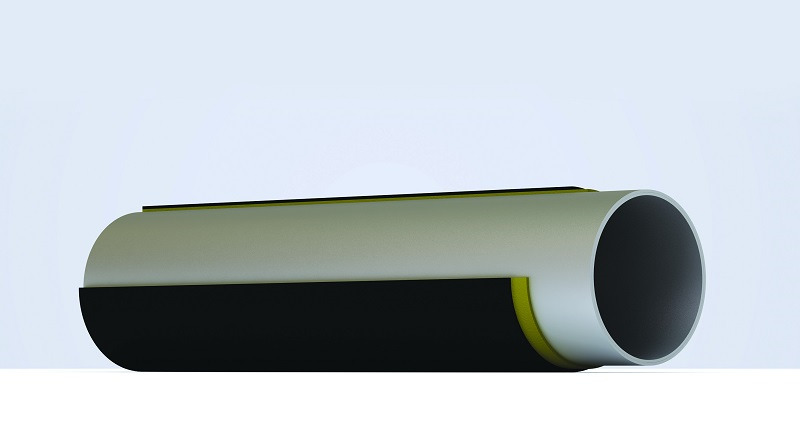

Polyethylene pipes

TMC Group Managing Company LLC provides polyethylene pipes (TU 2248-015-67740692-2010, TU 21.21.21-120-78682242-2022 for industrial applications: TU 2248-014-67740692-2010, TU 22.21.21-132-78682242-2022 for service and drinking water supply; TU 2248-017-67740692-2010, TU 22.21.21-134-78682242-2023 for gas pipelines).

Purpose

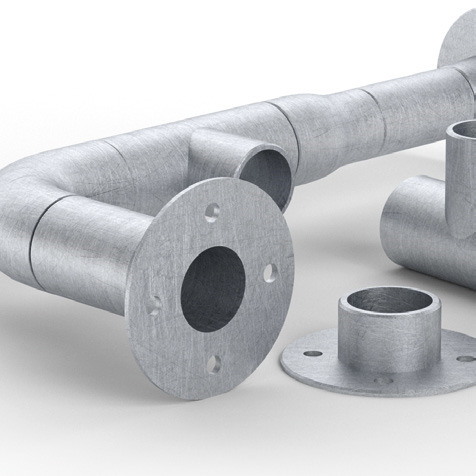

- For the construction of free-flow conduits for industrial application.

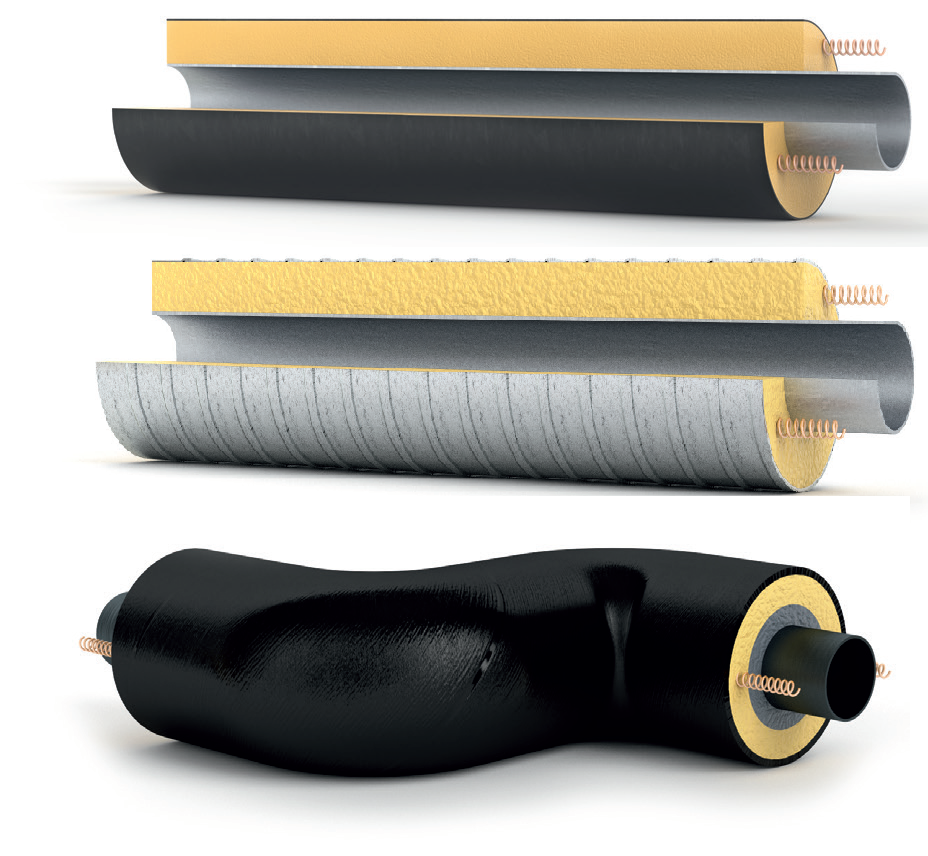

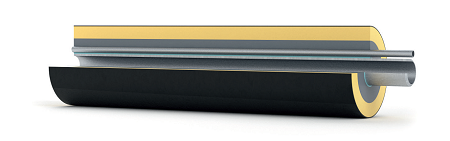

- For heat insulation of pipes as outer protective sheathing.

- For cable routing.

- For the construction of pressure pipelines for service and drinking water supply.

- For construction of underground gas pipelines at maximum gas temperature up to 104 oF and operating pressure up to 0.17 ksi.

Diameter range

- Industrial, Ø from 2.6 to 21.26 in.

- Drinking, as per GOST 18599.

- Gas, as per GOST R 50838.

- Supplied in straight sections, bundles.

Materials used

- PE 80.

- PE 100.

Advantages

- Absence of all types of corrosion.

- Low microbiological fouling.

- Polyethylene water-service pipes are environmentally friendly, toxicologically and bacteriologically safe.

- Good heat-insulating properties.

- No effect on the gustatory qualities and odor of drinking water.

- High durability (guaranteed service life of 50 years).

- Over time, the polyethylene pipe capacity does not deteriorate (there is no mechanical clogging of the water service pipe due to the low surface roughness).

- High resistance of polyethylene pipes to mechanical overloads due to such properties of polyethylene as elasticity.

- Polyethylene pipes are 2-4 times lighter than steel, which greatly facilitates their transportation and installation.

- The butt welding of polyethylene pipes is much cheaper, more reliable and easier, takes less time and does not require consumables (insulation, electrodes).

Documents

Chief specialist

Phone number

E-mail

See more