Internal and external corrosion-resistant coating of pipeline parts and assemblies

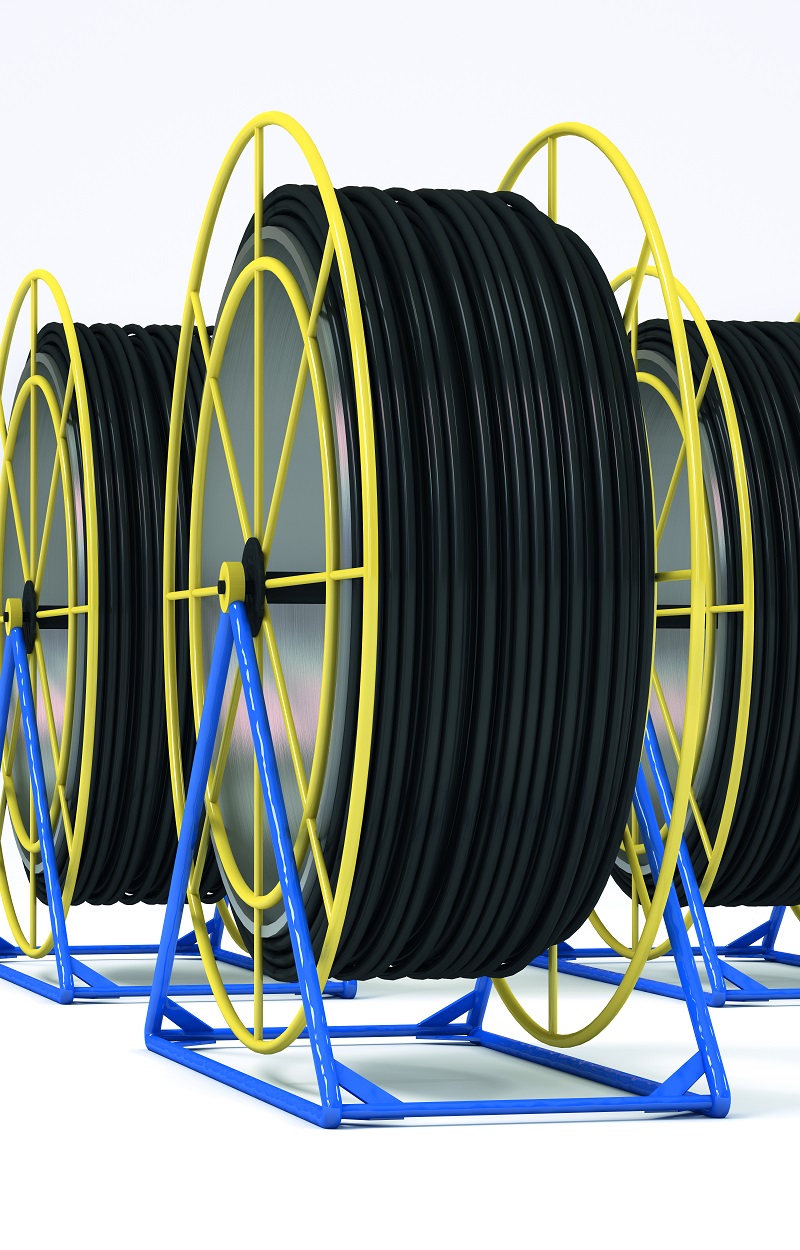

TMC Group Managing Company LLC provides internal and external corrosion-resistant coating of pipeline parts and assemblies (TU 1468-020-67740692-2012, TU 24.20.40-121-78682242-2022).

Details

Internal and external corrosion-resistant coating of pipeline parts and assemblies

The company sells pipeline assemblies and parts with internal and external protective corrosion-resistant coating based on paintwork and powder polymer compounds.

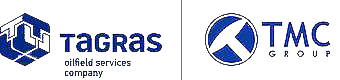

Assemblies are sections of a pipeline or other facility under construction consisting of combinations of assembly components: pipeline parts (tees, bent branches, crossings, bottoms, plugs, transition rings) and pup-joints.

Pipeline parts are connecting parts used in the construction of pipelines for various purposes. They are used for turns, bends, tilts, branches, changes in the diameter of the pipe, as well as in cases of temporary non-use of the pipeline.

The materials are characterized by chemical and thermal resistance, approved for use in appropriate environments and supported with laboratory test reports.

Assemblies are sections of a pipeline or other facility under construction consisting of combinations of assembly components: pipeline parts (tees, bent branches, crossings, bottoms, plugs, transition rings) and pup-joints.

Pipeline parts are connecting parts used in the construction of pipelines for various purposes. They are used for turns, bends, tilts, branches, changes in the diameter of the pipe, as well as in cases of temporary non-use of the pipeline.

Purpose

Intended for capital construction and overhaul of process and field pipelines (oil and gas pipelines, low-pressure water conducts of above-ground, underground and underwater routing). The temperature of the transported medium is up to +302 °F.Diameter range

2.24 to 20.87 in.Advantages

- The labor intensity of manifold pipeline production is reduced by an average of 25%.

- Organizational losses are reduced.

- Waste and material loss are reduced.

- Material storage costs on-site are reduced.

- It is possible to supply fabricated assemblies according to the schedule, to the needs of the installation of a particular object.

- Piping assemblies are manufactured as per customer’s drawings.

- Packed and delivered according to the scheme agreed with the customer: in boxes; on pallets; in bulk.

- 100% visual inspection and radiographic tests of the welded joint.

Coating features

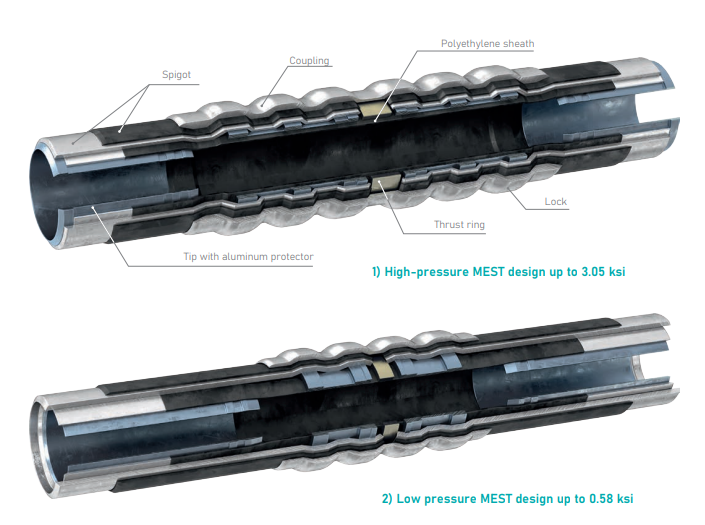

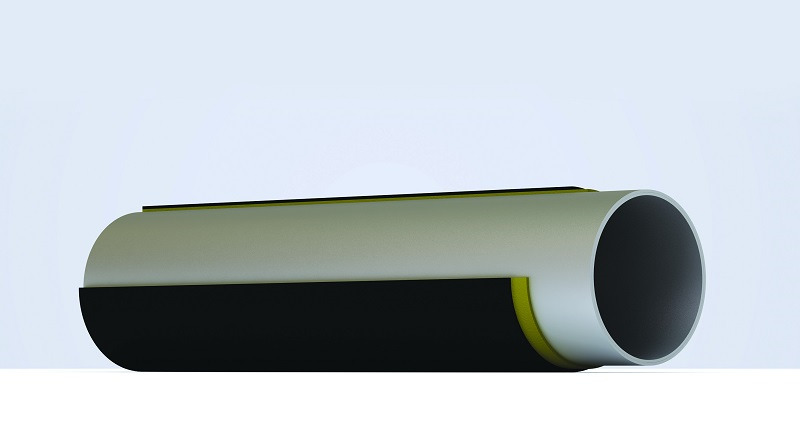

The internal coating of parts, assemblies of pipelines is performed as:- two-layer, consisting of a primer layer based on epoxy or epoxyphenolic primer and a coating layer based on epoxy powder paints;

- one-layer based on liquid epoxy, polyurethane paints.

Coating Properties

- It is resistant to oil, fuels, industrial and waste water.

- It is resistant to the damaging effects of stray currents.

- High degree of coatings adherence to the steel surface (adhesion).

- High mechanical strength.

Installation methods

- Pipeline assemblies and parts with internal protective corrosionresistant coating are installed on site.

- Construction works performed under especially complex conditions are simplified to the maximum for pipe installers when pipeline manifolds are supplied as enlarged assemblies, allowing 50 to 70% of all welding operations to be done in the factory.

- The time of construction and erection works is reduced by an average of 25%.

- Material storage costs on-site are reduced.

- Preparation of the ends can be made for welding or flanged joint.

Additional options

At the customer’s request for the purpose of protecting against external corrosion it can be combined with:- polymer coating based on powder materials;

- polymer coating based on liquid materials;

- polymer coating based on polyethylene or heatshrink materials.

End preparation options

- For welded joint complete with protective sleeves.

- For welded joint with mounted corrosion-resistant steel tips.

- For welded joint with the application of metal-sprayed coatings.

- For flanged joints.

The materials are characterized by chemical and thermal resistance, approved for use in appropriate environments and supported with laboratory test reports.

Possibilities of shop fabrication of piping assemblies

- Transfer of up to 70% of all labor costs from the installation site to the workshop.

- Mechanization of majority of production operations.

- Use of high-performance machines and mechanisms, assembly and welding jigs.

- Semi-automatic welding methods.

- Implementation of new design solutions in manifold designing.

Chief specialist

Phone number

E-mail

See more