Metal-plastic pipes and pup-joints

TMC Group Managing Company LLC provides metal-sprayed coating of end sections of pipes and pipeline parts with an internal corrosion-resistant coating (MPK).

Details

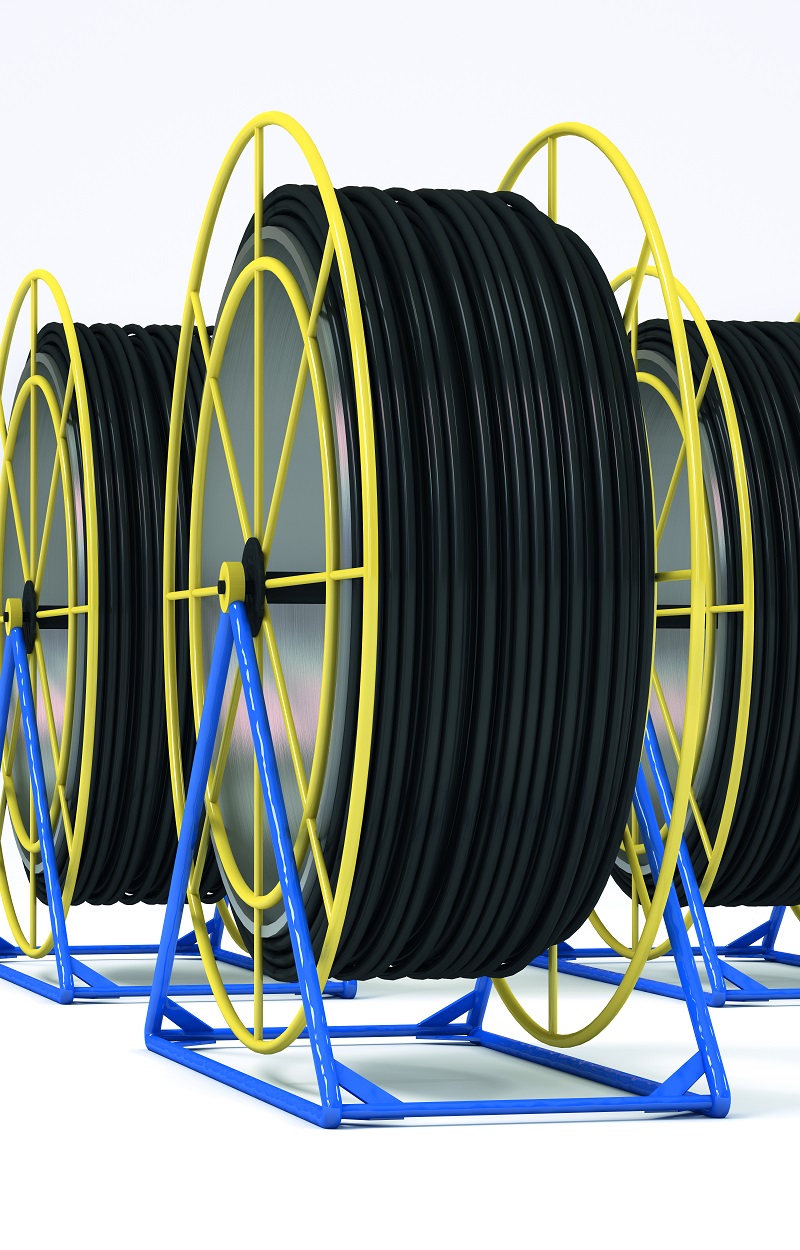

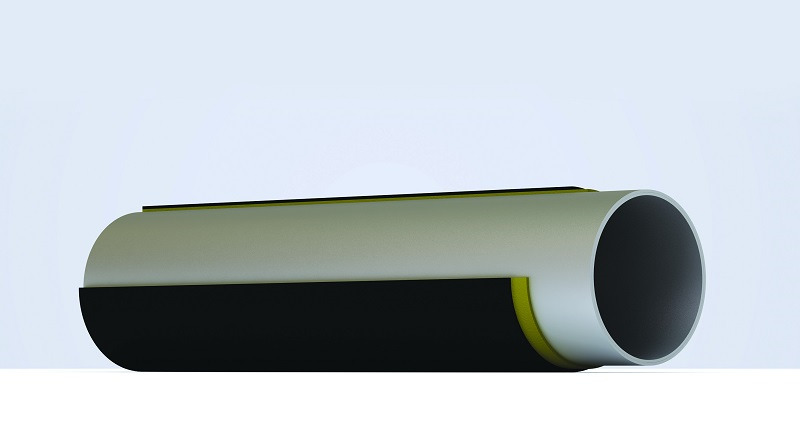

Metal-plastic pipes and pup-joints

Metal-plastic pipes and pup-joints with diameter up to 12.8 in. with maximum wall thickness of 0.87 in. represent a steel pipe, a pup-joint pipe with polyethylene (for underground routing) or paint coating (above-ground routing), lined with polyethylene pipe (shell) on the inside and fixed with tips made of:

- structural carbon steel (MPT—metal-plastic pipes);

- corrosion-resistant steel (MPTK—metal-plastic corrosion resistant pipes).

- Normal—operating temperature up to +104 °F.

- Heat-resistant—operating temperature above +104 °F, but NOV +176 °F.

Purpose

MPT, MPTK and MPTK (1) are designed for the construction of pipelines transporting:- oil-field water, refinery water, and fresh water in the reservoir pressure maintenance system;

- corrosive environments of the chemical, petrochemical, oilrefining industries to which polyethylene is chemically resistant.

Advantages

The structural reliability is ensured by:- Effective protection of the inner surface of steel pipes from aggressive effects of the transported medium.

- Effective protection of the outer surface of steel pipes from the effects of soil corrosion by polymer, powder or paint coating.

- Protection of the welded joint area with a corrosion-resistant tip.

- Structural durability—service life of at least 30 years.

- No change in the pipeline throughput over the years of operation due to the absence of buildups.

Products are supplied complete with pipeline parts

- Bent branches from 5° to 120° with a ratio of 1° and diameter of up to 6.26 in.

- Bent branches with weldnecks from 3.5 to 12.8 in. in diameter.

- Crossovers and T-bends from 3.5 to 12.8 in.

- S- and L-shaped bends up to 6.26 in.

Reliability is ensured by

- Observation of the welding conditions in the field. The company provides author’s supervision and engineering support for the first 1.864-3.107 mi of pipeline with training for the construction crew.

- Additional visual supervision of the welding process by changing the color of the thermal indicator material applied to the length of the uninsulated section at the request of the customer.

Documents

Chief specialist

Phone number

E-mail

See more