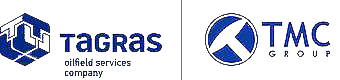

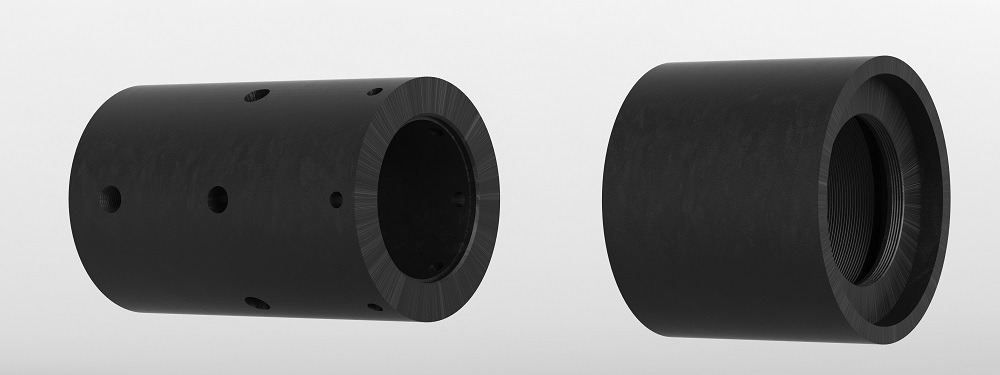

TMC POWER MAN™ pneumohydraulic drive of the downhole sucker-rod pump with 30 to 140 kN load on the wellhead rod

TMC Group Managing Company LLC manufactures and supplies pneumohydraulic drive of pump wells TMC POWER MAN ™.

Details

TMC POWER MAN™ pneumohydraulic drive of the downhole sucker-rod pump with 30 to 140 kN load on the wellhead rod

Purpose

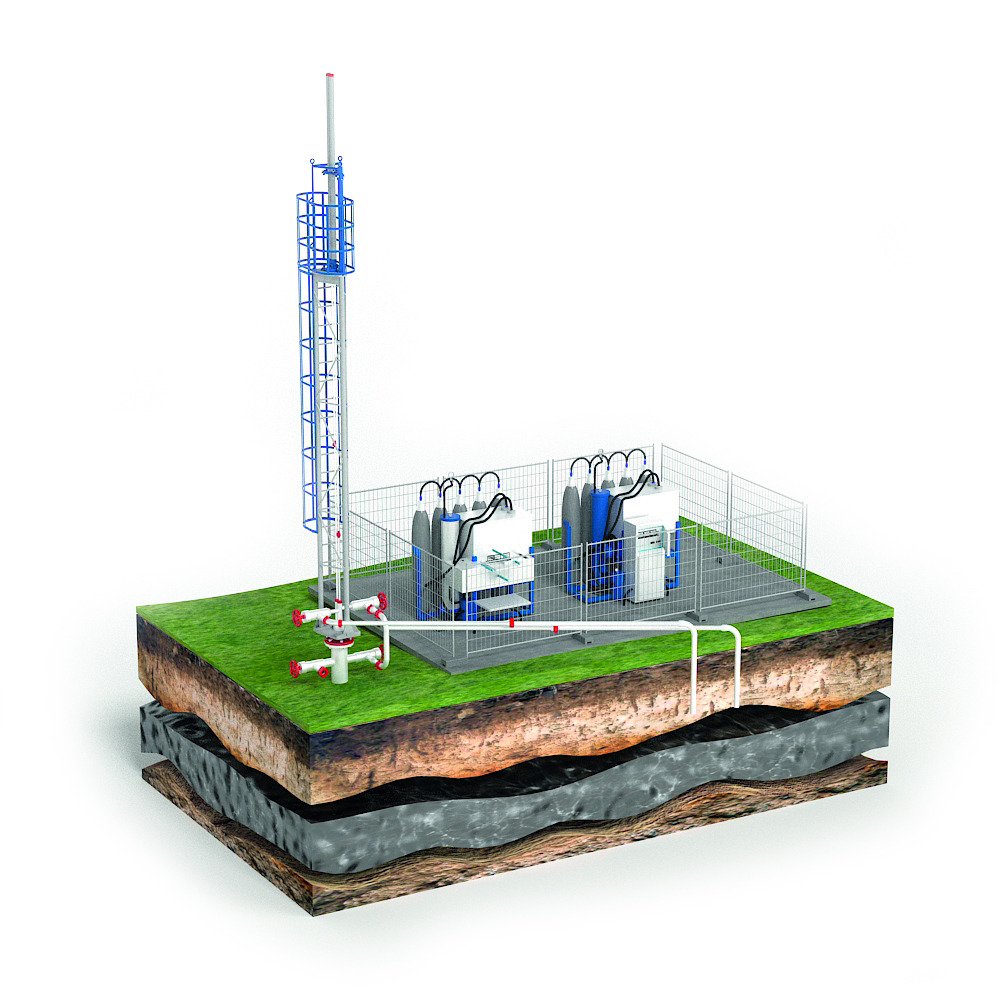

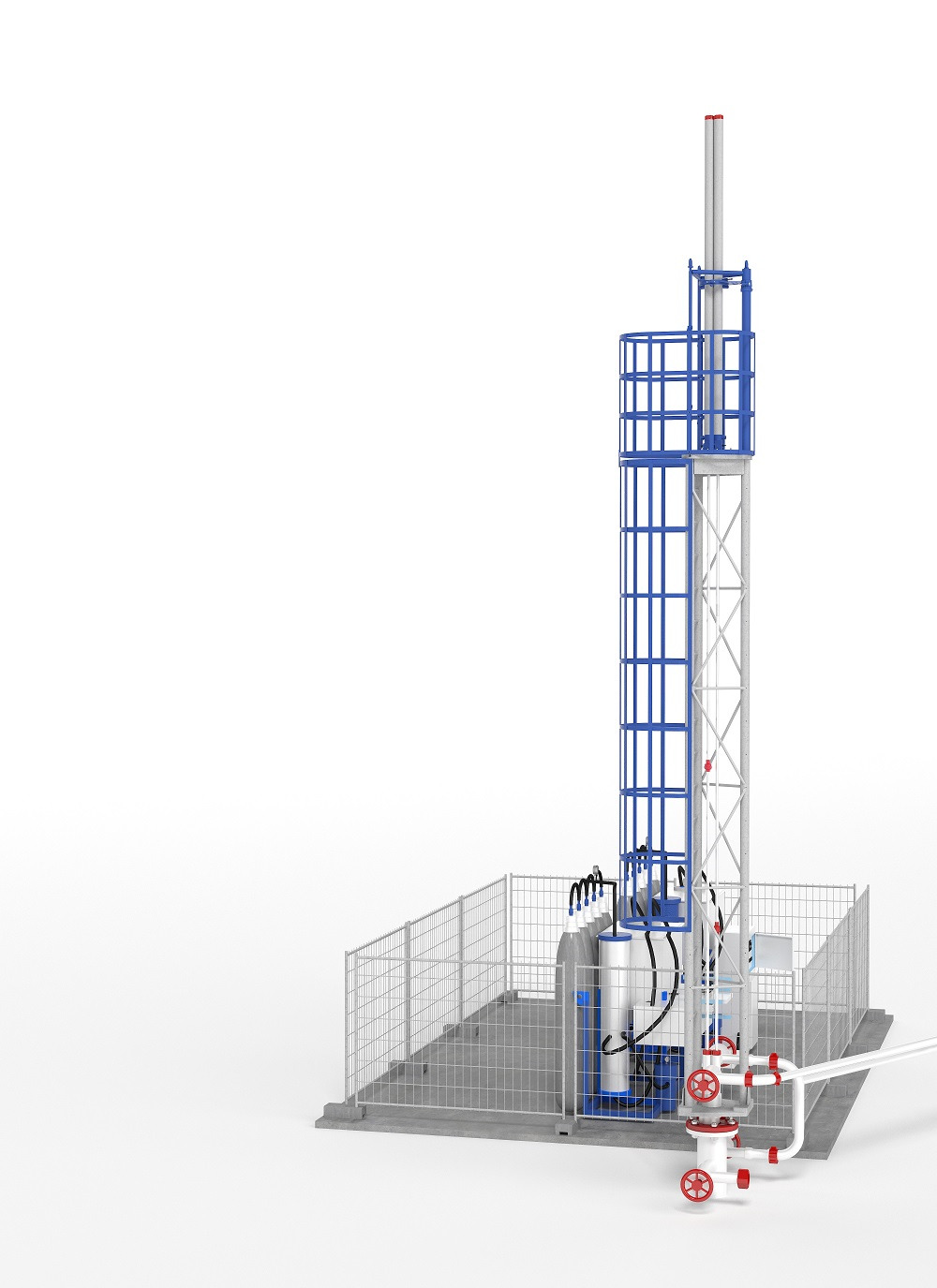

The TMC ROWER MAN™ pneumohydraulic drive is intended to provide the reciprocating motion of a downhole sucker-rod pump when pumping out fluids from oil wells.

Field of application

- Well development after drilling and workover.

- Operational selection of optimal well operation parameters during the development period.

- Operation on wells equipped with single-lift equipment for the separate production (ESP).

- Watercut studies owing to the possibility of operational changes in parameters of operation of the downhole sucker-rod pump plunger when switching from one formation to another (within 5 minutes by one operator).

- Operation of intermittently operating well stock that has been rendered inactive. Possibility to operate the downhole suckerrod pump in wide ranges; the minimum stroke length is 0.82 ft.

- Conducting reestablishment works on wells with the risk of rod string catching and jamming.

Advantages over traditional drives

- Multiple times lower specific quantity of metal and weight compared to other downhole sucker-rod pump drives up to 70%.

- Reduction of assembling and dismantling and commissioning time by up to 60%.

- Remote control of the hydraulic drive and automatic maintenance of operating modes.

- Continuously variable number of swings and pump plunger stroke length without stopping the drive by one operator within 5 minutes.

- Delay of the pump plunger in the upper position (an increase of the pump fill rate).

- Availability of the spudding function (to take the well out of jamming).

- Reducing energy costs by up to 30%.

- The hydraulic drive is programmed for maximum well delivery and for optimization of specific power consumption and dynamic level.

- Reduced equipment wear and increased well’s inter-overhaul time.

- Operation of three wells with a single hydraulic drive (special version of the hydraulic drive) °F ™ Ø.

Support equipment (at customer's option)

- Rod rotator (RR).

- Special shelter (booth) for the hydraulic power unit in explosionproof and hufter-proof versions.

- Remote control function with the possibility of changing parameters, remote monitoring, and online control of hydraulic drive operation from the operator console.

Characteristics

Documents

Chief specialist

Phone number

E-mail

See more