Сompany class casing pipes with threaded connections of TMC-OTV-6,35-245, TMC-SRV1 type and casing pipes in accordance with GOST 632-80 and TS 14-3Z-29 with OTTM, HSE, BUTTRESS threaded connections.

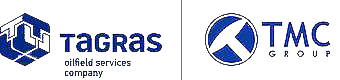

High strength highly sealed casing string TMC-OTV-6.35

Casing strings series OTV produced in accordance with Technical Requirements TU 1327-009-20970456-2015 are used to case oil wells, gas wells of complicated profile and the wells in which there moves the heat transfer medium at a temperature of up to 250 oC.

The uniqueness of the design consists in the following: sealing of the threaded joint due to interference fit contact at C point of the toroidal seal band of the nipple with the female cone in the collar.

Advantages of threaded Joints:

1. Improving the quality of pipe assembly on the well by means of free entry without rotating the nipple into the collar at a depth of 12 threads which reduces the probability of the threads getting cocked and ensures distribution of the load from the weight of the pipe being screwed on over several mutually contacting threads.

2. Increasing the axial load for extension and compression in the threaded joint F-6,35, virtually to the load which the casing string body withstands. The load increases as result of redistributing it over the threads of incomplete profile in area g, the metal cross section area under which increases;

3. Equal distribution of axial load over the threads as a result of gradually increasing the thread depth from the indicating band (5) to the main plane;

4. Facilitating visual control of thread screwing completion by comparing the collar end with the beginning of the wide circular band (5);

5. Increasing reliability of the casing string when lowering it into severely curved wells by optimizing gaps near the threads as well as the toroidal and taper design of threaded joint sealing unit.

High strength highly sealed casing string TМC-SRV1

Casing strings TМC-SRV1 produced per Technical Requirements TU 1308-100-78691656-2015 by TMC-Drilling Service LLC are used to case oil and gas wells of complicated profile.

Advantages:

Sealed geometrical interface of the threaded profile and two abutment elements.

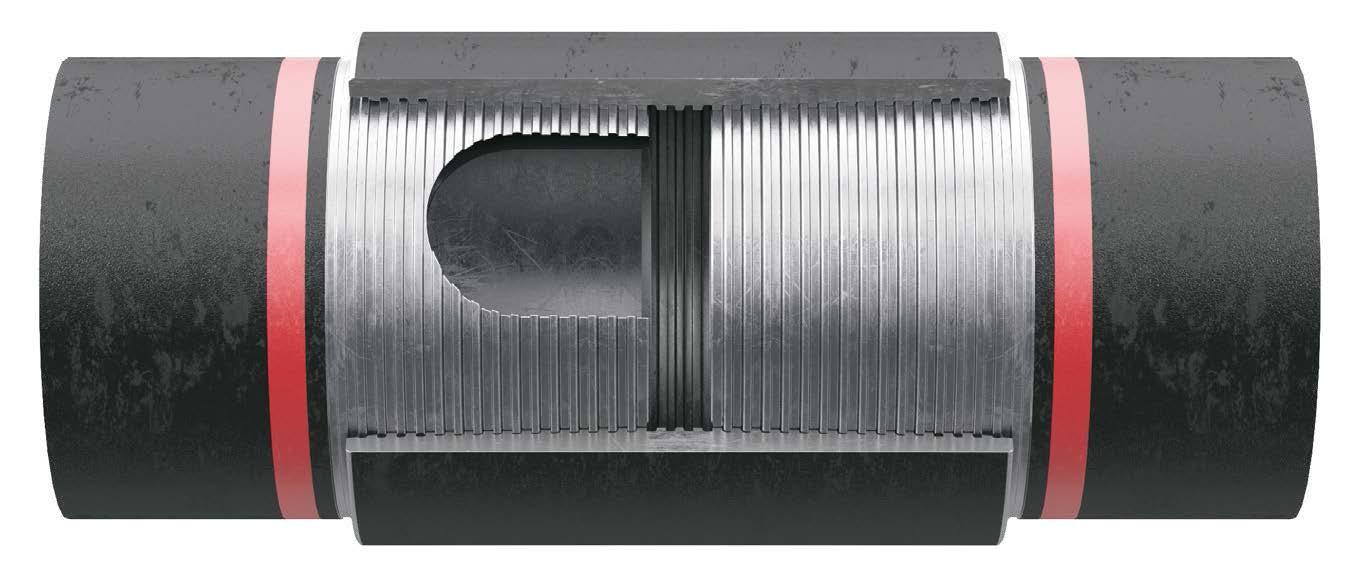

Design Features of the Threaded Joint:

1. On the pipe, threads are cut per GOST equivalents and, in addition, a sealing abutment element is installed which ensures joint sealed interface between the threaded profile and two abutment elements (ridge on the pipe and the bore in the collar) “metal-to-metal”.

2. In the entire interface of the threaded profile and sealing abutment elements, there is no gap between the outside surface of the seal on the pipe nipple and in the collar bore. Geometry is sealed on the geometrical dimensions of the thread profile angle interface, on the nipple end and in the bore , i.e. on the collar end “metal-to-metal” as well as on the diameters of the sealing elements. Existence of two turns of the incomplete thread profile on the sealing diametrical surface of the pipe nipple sealing element, which serves as a damper, when the joint operates, is a distinguishing feature of the geometry and a competitive advantage of the Management Company TMC Group LLC. After triple screwing together and unscrewing of the joint, the turns of the incomplete profile disappear from the seal surface.

3. The joint allows considerable increase in the make-up torques and in the bearing capacity of the threaded joint as well as increases reliability when combined loads act cumulatively in the form of extension, compression and inner hydraulic pressure.

High strength highly sealed casing string TMC-SRV2

Casing strings TMC-SRV2 are used to extract high viscosity oil by steam assisted gravity drainage (SAGD) which presupposes drilling two parallel horizontal wells to inject steam into the formation and cracking viscous oil as well as for oil extraction.

Unique design:

This joint is characterized by high compression strength, tensile strength, bending strength and corresponds to the CAL IV requirements level which confirms that it can be used in the most severe conditions of oil production. Another special feature of the threaded joint TMC-SRV2 is its capability of being assembled on the inclined support of the drilling rig.

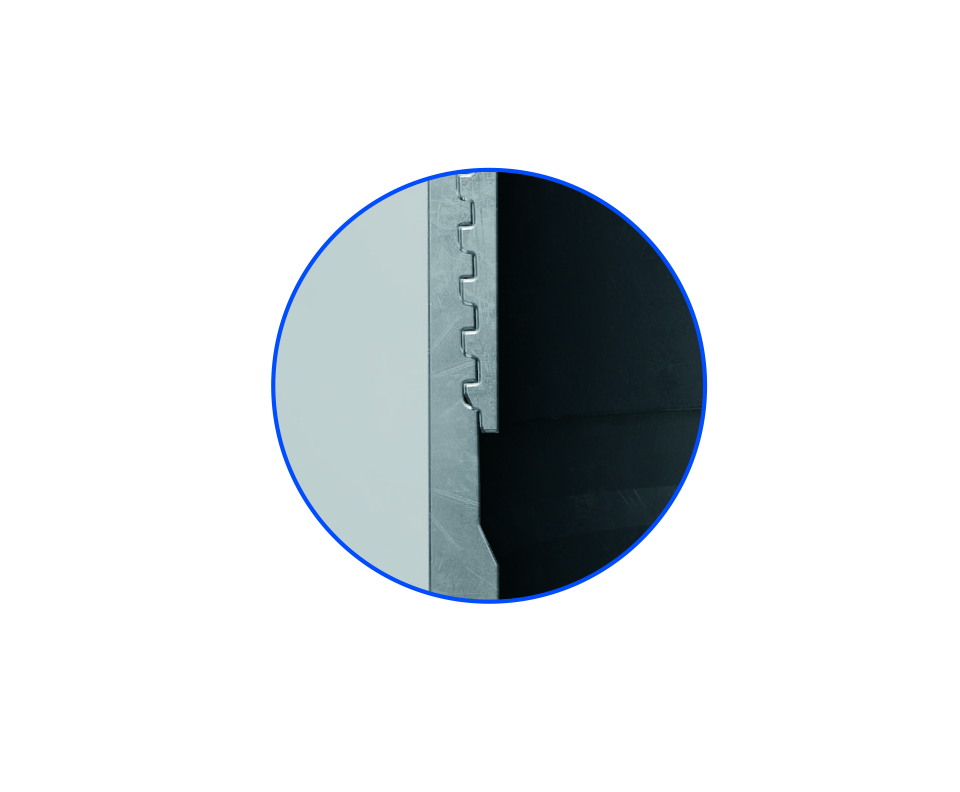

Advantages of the threaded Joint “DOMINANT”

• On the pipe, the thread profile is cut and, in addition, a sealing abutment el ement is made which ensures joint geometrical interface of the threaded profile and the sealing unit on tw o toroidal surfaces “metal-to-metal”.

• In the entire interface of the threaded profile and sealing abutment elements, there is no gap between the outside surface of the seal on the pipe nippl e and in the collar bore. Geometry is sealed on the geometrical dimensions of the threaded profile angle interface, the nipple end and the toroidal seal.

• The joint allows considerable increase in the make-up torques and in the bearing capacity of the thr eaded joint as well as increases reliability when combined loads act cumulatively in the form of extension, compression and inner hydraulic pressure.

• Torque values are different from those shown in the table of minimum, optimum and maximum Mcr. For casing strings 245*8.9mm – Mcr = 42kN.

Casing string with increased operating reliability and BUTTRESS profile

The coupling joint of casing strings with buttress profile thread is designed to construct and operate vertical wells of oil, gas and gas condensate fields. The BUTTRESS joint combines the functions of a “lead screw” and the joint hydraulic seal which ensures good reliability of the joint compared to equivalents.

Advantages:

Acceptance of increased axial loads in one direction, the thread form allows reduction in friction coefficient and doubles the resistance to displacement for reasons of increase in profile.

Design features of the thread joint:

1. The design feature of the casing strings with BUTTRESS threads is high resistance of the threaded joint to tensile loads. The profile of the BUTTRESS threads looks like a trapezoid with unequal sides (pitch 5.08 mm, cone 1:16). Embedment side which accepts load at the time of fitting the pipe joint into the coupling part, operating by ompression, is made at an angle of 10 oC. That ensures easy fitting of the pipe into the coupling and reduces thread sticking.

2. Three degree deviation of the profile support side would reduce the risk of the pipe threads coming out of the mating with the coupling thread when it is stretched hard or bent.

3. Seal is ensured by pressure of the thread sealant in the design gaps of the threaded joint profile. If specified by user, it is permissible to produce a threaded joint with fluoroplastic sealing ring in the coupling.

4. Quality control of screwing the pipes together by machine is made by position of the coupling end with reference to the triangle sign shown on the pipe. Correctly assembled joint is considered to be the following one: when the coupling end is one turn short of reaching the triangle sign base.

Casing string with increased operating reliability and OTTM profile (GOST 632-80)

The coupling joint of casing strings with buttress profile thread is designed to construct and operate vertical wells of oil, gas and gas

condensate fields.

Design features of the thread joint:

1. The design feature of the casing strings with OTTM threads is high resistance of the threaded joint to tensile loads. The profile of the OTTM threads looks like a trapezoid with unequal sides (pitch 5.08 mm, cone 1:16). Embedment side which accepts load at the time of fitting the pipe joint into the coupling part , operating by compression, is made at an angle of 10 oC. That ensures easy fitting of the pipe into the coupling and reduces thread sticking.

2. Three degree deviation of the profile support side allows the risk of the pipe threads coming out of the mating with the coupling thread to be reduced when it is stretched hard or bent.

3. Seal is ensured by pressure of the thread sealant in the design gaps of the threaded joint profile. If specified by user, it is permissible to produce a threaded joint with fluoroplastic sealing ring in the coupling which provides an additional sealing unit.

4. Correctly assembled joint is considered to be the following one: when the coupling end coincides with the end of thread runout or is no more than 5 mm short of reaching it.

The lineup of pipes with BUTTRESS and OTTM profile corresponds to GOST 632-80 and has the following physical and mechanical indicators.